4 November 2024

Saab’s Seaeye SR20 eWROV succeeds in milestone water trials

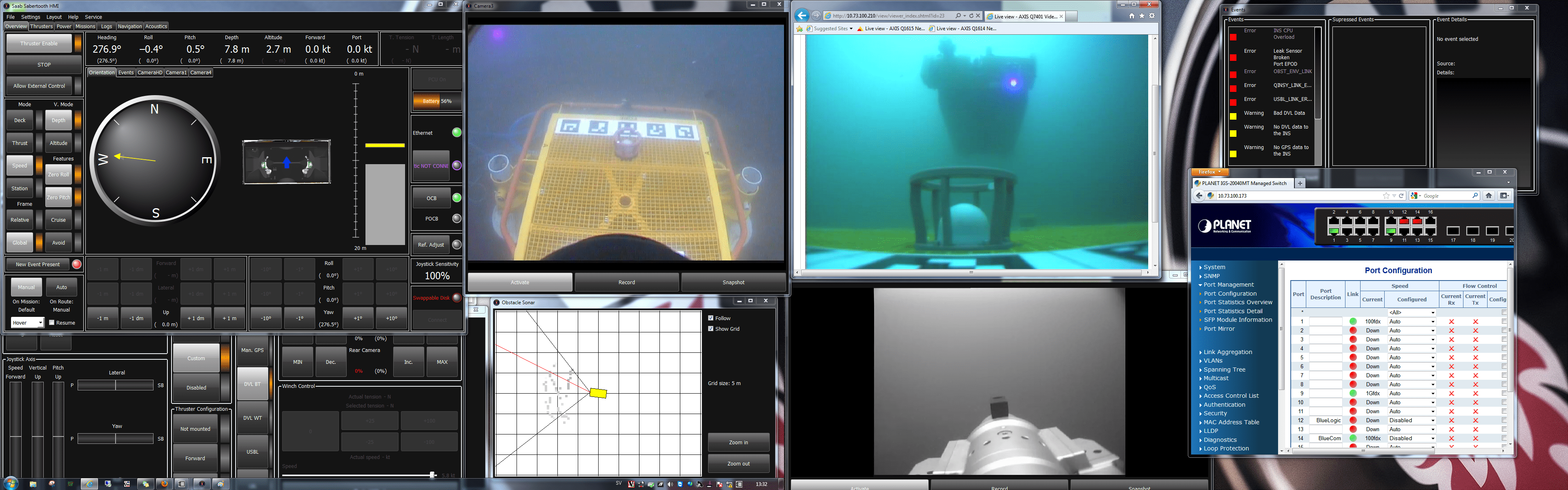

Saab UK announces that the Seaeye SR20 eWROV, its most advanced fully-electric work-class remotely operated vehicle, has successfully completed inshore water testing.

The SR20 successfully completed a dedicated period of water trials last month, marking a significant milestone for the robotic vehicle’s development.

The testing was a key part of the verification and validation work package, testing against the specification, measuring performance, and stressing the Remotely Operated Vehicle (ROV) as a system. In particular, the SR20 demonstrated its high degree of precise manoeuvrability and dexterity, using both manual joystick control and automation. This testing has paved the way for sea trials which will take place in spring 2025.

Andy Fraser, Managing Director at Saab UK, said:

“The SR20 going to water trials is a huge milestone in Saab UK’s journey to take electric ROV capabilities to the next level, focusing on eco-responsibility and greater efficiency. We’re thrilled that the trials were a success and I look forward to seeing what the next step is for this ground-breaking vehicle.”

The SR20 is Saab UK’s highly capable and environmentally-conscious work-class underwater vehicle, which is designed for operational concepts such as resident deployment and over-the-horizon control. The all-electric vehicle, which uses limited oil (reducing its environmental footprint), sets itself apart with its exceptional thrust and performance, electric manipulators, and impressive efficiency compared to hydraulic systems.

Ocean Infinity is the SR20’s launch customer, transforming operations using innovative technology as they develop a fleet of uncrewed robotic vessels.

2 July 2024

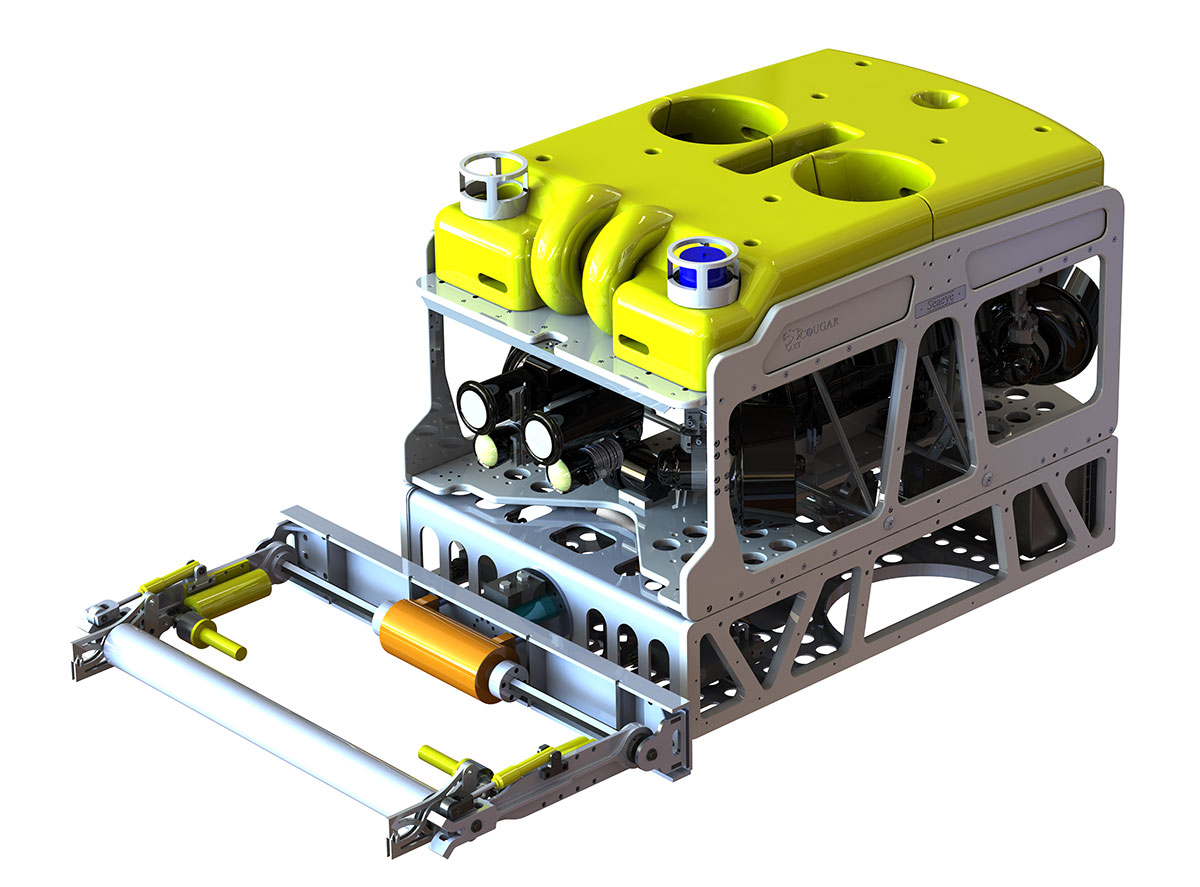

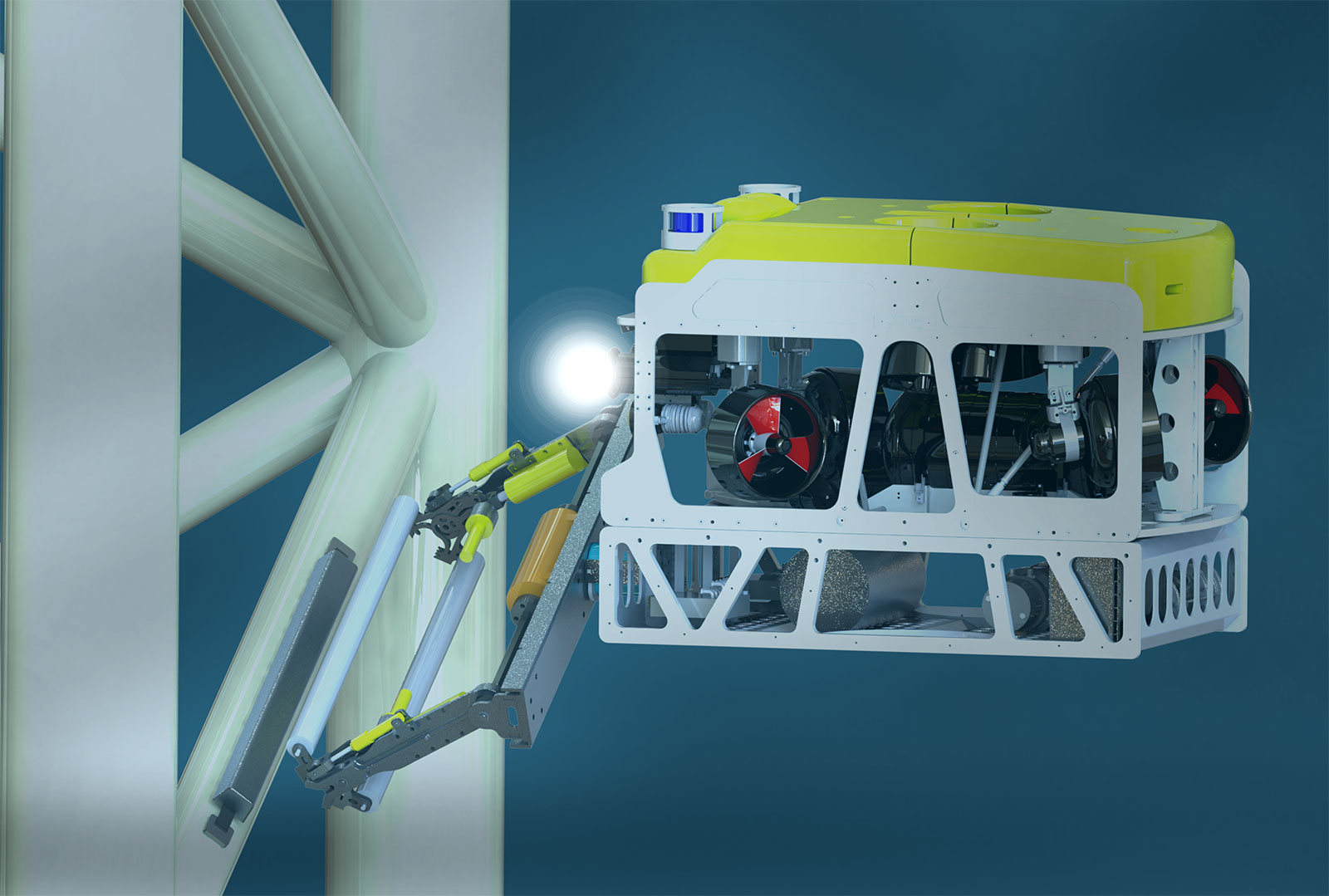

Saab’s Seaeye Cougar-XTi stood out due to its remarkable carrying capacity, a crucial factor for HBC Group’s operations. The Cougar-XTi is a highly flexible and extremely powerful electric ROV, depth rated to 2000m. The ROV is fitted with six 500 Volt, DC thrusters that provide exceptional thrust for stable vehicle operations in high current environments.

These features allow the transport of survey equipment that was previously too large for HBC Group’s existing ROVs, catering to the specific needs of clients, particularly those in offshore wind farms.

The versatility of the Cougar-XTi extends to carrying specialised tools for hydrographics and geophysical services. HBC Group utilises PMAC Group’s system for cathodic protection measurements, and the manipulator arms play a crucial role in non-destructive testing.

Christian Eilersen, CEO at HBC Group Said:

“We are thrilled to elevate our offshore inspection capabilities with the Seaeye Cougar-XTi. This advanced ROV enables us to meet the unique needs of our clients in offshore wind farms, and its addition to our fleet reflects our ongoing commitment to excellence and innovation in the field of offshore inspections.”

Looking ahead, HBC Group plans to deploy the Cougar-XTi for daily inspections, allowing them to bid on tenders that were previously inaccessible due to payload constraints. The order/capability is expected to open new avenues for the company in the offshore wind sector.

Jon Roberston, Managing Director at Saab Seaeye said:

“We’re thrilled to empower HBC Group with the advanced Seaeye Cougar-XTi. This sale underscores our commitment to delivering top-tier equipment, redefining standards for efficiency and reliability in offshore operations.”

In addition to the Cougar-XTi, HBC Group highlighted the success of its previous ROV purchase with Saab, the Seaeye Tiger. The company noted its reliability and higher uptime compared to previous ROVs. The Tiger has played a crucial role in recent inspections on offshore wind farms in Denmark, the UK, and Germany, particularly in waveform inspections.

The addition of the Cougar-XTi to HBC Group’s fleet signifies the company’s commitment to staying at the forefront of technology in the offshore inspection services sector.

29 March 2024

Owner of largest fleet of Seaeye Falcon ROVs buys five new units

Aberdeen-based Underwater Contracting (UCO), owner of the largest fleet of Saab UK’s Seaeye Falcon remotely operated vehicles (ROVs), has purchased five new units for a total of 38 Falcon systems.

UCO said it had expanded its fleet in response to major new multi-year contract wins across all sectors which will see it provide a range of services in Europe, North America and the Middle East.

In addition, the company announced it had made significant investment in additional equipment and now holds a stock of £250,000 dedicated Saab Seaeye Falcon spares and more than £350,000 worth of auxiliary equipment ranging from manipulators to station holding and everything in between.

“Adding these additional systems to our fleet will enable us to respond to the upsurge in business and the major new contracts we have won in recent months,” said Mick Bower, UCO Managing Director.

“We have also made significant investment in adding to our stock of in spares and auxiliary equipment for the Falcons, so we can respond immediately to any issues or additional requirements that might arise during the delivery of our services for existing and new clients. Providing excellent customer service is integral to the way we run our business and having these items to hand when we need them, avoids unnecessary delays for our clients.”

6 October 2023

INDONESIAN CUSTOMER SAYS SEAEYE FALCON TOPS OTHER BRANDS

Jakarta-based PT Fabila Teknik Sejahtra, has bought Saab’s Seaeye Falcon remotely operated robot, declaring it superior to other brands.

PT Fabila’s marine and offshore undertakings include condition inspection and surveys throughout Indonesia.

The diving company will deploy the Falcon in their marine and offshore contracting services support across Indonesia.

“The Falcon’s performance is far better than other brands and is the clear choice of many other diving companies,” says PT Fabila director, Enif Widoyoko,

Important to Fabila is the Falcon’s reputation for mastering the challenge of strong currents and being “tougher” than competitive brands, Enif Widoyoko says.

He also finds that Saab has an advantage concerning support:

“Information such as the operating manual, wiring diagrams and troubleshooting guides are complete and comprehensible, spares are easy to order and their distributor, Unique, is easy to work with.”

As PT Fabila’s marine and offshore undertakings include condition inspection and surveys, their Falcon comes fully equipped for the tasks including a Tritech Gemini sonar, a cathodic potential probe kit, Cygnus ultrasonic thickness gauge and a rotary wire cleaning kit.

For diving companies, the Falcon plays a vital role by undertaking missions too hazardous for divers, such as where the depth of water and strength of current become dangerous for divers.

The Falcon can also improve diver safety and increase efficiency by pinpointing and examining locations of interest before sending down divers.

The world’s most successful robotic vehicle in its class, the Seaeye Falcon has a reliability record covering over a million hours underwater.

Just a metre in size, it is easily manhandled and its intelligent control architecture, combined with five powerful thrusters allows precise manoeuvrability in turbulent waters amongst complex structures, whilst loaded with various cameras, sensors and tooling typically found on much larger robotic vehicles.

.jpg)

The world’s most successful robot, the Seaeye Falcon, with a million hour underwater record, can work in strong currents at a wide range of both complex and hefty tasks whilst handling an array of tooling, sensors and skid configurations.

Saab Seaeye is world leader in electric underwater robotics.

PT Fabila Teknik Sejahtra is committed to advancing technology and services in the marine and offshore industry.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Enif Widoyoko

PT Fabila Teknik Sejahtra

+ 62 21 830 8618

Email Enif Widoyoko

www.fabilats.com

7 September 2023

MORE SEAEYE FALCONS FOR UCO

Owners of the world’s largest fleet of Saab UK’s Seaeye Falcons, Underwater Contracting (UCO), has ordered a further six Falcons, boosting their fleet to 33 vehicles.

.jpg)

Seaeye Falcon is capable of handling UCO’s hugely successful FOOVER mortality recovery system.

This follows the award of further major contracts in the aquaculture, renewable, and oil and gas sectors to UCO that will see the Falcon fleet working continuously over multi-year contracts providing a range of services in Europe, North America and Australia.

Specialists in ROV operations, UCO has successfully deployed Seaeye Falcon underwater vehicles since 2018 across three continents covering various sectors of industry.

In that time UCO has productively utilised the power and intelligence of the Falcon system when designing and developing industry-leading technologies, including their FOOVER Mortality Recovery system, NETFIX Net Repair system and G-LANCE Cage Cleaning system, inspection cleaning tools.

They chose the Falcon as the world’s top selling underwater robotic vehicle in its class and for its versatility.

The Falcon is designed and manufactured at Saab UK’s Fareham site.

Underwater Contracting Ltd (UCO), based in Aberdeen, is a leading provider of underwater services for the maintenance of aquaculture sites throughout Scotland, North America, Canada and Europe and is part of the Ocean Marine Group.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Mick Bower

Underwater Contracting Ltd

+44 (0)1224 872861

Email Mick Bower

www.underwatercontracting.com

3 August 2023

SEAEYE FALCON KEY IN JAPAN’S OFFSHORE WIND ENERGY

Japan’s expanding offshore wind industry has added a further Seaeye Falcon underwater robot as a key operational resource for working in complex environments.

.jpg)

The world’s most successful robot, the Seaeye Falcon has a proven record across many different markets, working reliably at a wide range of both complex and hefty tasks whilst handling an array of tooling, sensors and skid configurations.

Tokyo based systems provider Marimex says Japan’s wind power construction operators value the Falcon for being a compact and powerful robot that is ideally suited for shallow waters and strong currents.

The small footprint of the metre-sized Falcon is also important for offshore energy operators as construction is carried out using fleets of small service vessels needed in shallow waters.

Growth in Japan’s offshore wind power construction comes as the Japanese Government seeks to achieve carbon neutrality by 2050.

Marimex says that the Falcon’s broad operational capability means that not only can it be used for preliminary surveys, but also for post-construction maintenance monitoring and many other applications.

As the world’s top selling robotic vehicle in its class, the Falcon has a reliability record covering over a million hours underwater.

The success of the highly portable Falcon comes from combining intelligent control architecture with five powerful thrusters to enable precise manoeuvrability in turbulent waters amongst complex structures, whilst loaded with a wide range of cameras, sensors and tooling, typically found on much larger robotic vehicles.

Saab Seaeye is world leader in electric underwater robotics.

Marimex Japan KK is primarily involved in importing and selling ROVs and providing maintenance services and is a Saab Seaeye distributor.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Mifuyu Shoji

Marimex Japan KK

+81 3 5858 8467

Email Mifuyu Shoji

www.marimex.co.jp

17 May 2023

SEAEYE FALCON PICKED FOR ARCHAEOLOGY AND OFFSHORE ENERGY

Italy’s DST (Deep Sea Technology) has chosen a 1000m-rated Saab Seaeye Falcon DR robotic vehicle to support archaeological research and offshore energy.

DST divers working on the wreck of a Spanish galleon off the Sardinian west coast.

The Seaeye Falcon DR will be employed by Naples-based DST, a commercial diving business, across its operations supporting offshore energy and maritime archaeology in both shallow and deep waters. The Falcon package includes a Tritech Super SeaPrince sonar and skid-mounted five function manipulator and rope cutter.

“The Falcon DR will extend our operational capabilities,” says Alessandro Scuotto, CEO of DST. “It will operate in both single configuration and for diver support and we plan to further enhance the vehicle with new system options in the future.”

The Seaeye Falcon has a proven record globally in many marine archaeological missions involving filming, recording, surveying and delicately recovering artefacts when appropriate.

During diving operations, the Falcon can helpfully preview dive sites, watch over divers and save time by transporting tools and materials back and forth.

As the world’s most successful robotic vehicle in its class, the Seaeye Falcon has a reliability record covering over a million hours underwater.

Its success comes from having the power and intelligent control to handle a wide range of resources for undertaking numerous intricate and demanding tasks in strong currents and turbulent waters.

Just a metre in size, the Falcon is easily manhandled, and its iCON™ intelligent control architecture, combined with five powerful thrusters, allows precise manoeuvrability amongst complex structures, whilst loaded with various cameras, sensors and tooling, typically found on much larger robotic vehicles.

.jpg)

The world’s most successful robot, the Seaeye Falcon has a proven record in many marine archaeological missions involving filming, recording, surveying and delicately recovering artefacts when appropriate.

Saab Seaeye is world leader in electric underwater robotics.

Deep Sea Technology (DST) operates in the underwater sector, both in deep and shallow waters, specialising in a wide range of services including the design, construction, installation and maintenance of subsea pipelines and offshore structures, underwater research and recovery.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Alessandro Scuotto

DST (Deep Sea Technology)

+39 081 553 5816

Email DST

www.deepseatechnology.com

4 May 2023

LOTOS CHOOSE SEAEYE LEOPARD FOR BALTIC FIELDS

LOTOS Petrobaltic, part of multi-energy concern ORLEN, has ordered Saab’s Seaeye Leopard work class robotic vehicle to service underwater infrastructure within Poland’s B3 and B8 oil fields in the Baltic Sea.

.jpg)

LOTOS Petrobaltic chose the Leopard for its operational versatility, voting it the best amongst competitors.

After evaluating other work vehicles on the market, LOTOS Petrobaltic chose the Seaeye Leopard for its versatility and ability to accommodate far more equipment options for a wider range of tasks.

Current tasks include the comprehensive inspection of underwater structures, construction cleaning, cutting, dredging for inspection, basic support for head installations and support for diving teams.

The Leopard’s adaptability is particularly important for LOTOS Petrobaltic. The vehicle’s design means it can be expanded and configured in the future to perform comprehensive measurements and underwater works and inspections for a wide range of customers. It will be equipped with a survey package to include multi-beam sonar, LIDAR and pipetracker.

Their current Leopard configuration includes a Sonardyne DVL/INS survey system, Sprint-Nav INS, Digital Edge recording and event system, five cameras including Kongsberg HD system, also a One Laser for video and measurement, Tritech Super Seaking sonar, a seven-function manipulator, Schilling Orion gripper, electric torque tool, rotary disc cutter, WeSubsea dredge system, FlexiClean cleaning tool, water jet system and caviblaster, Cygus ultrasonic thickness gauge, multiplex survey pod and tooling sled.

The Leopard package also includes a tophat tether management system (TMS), an ‘A’ Frame launch and recovery system (LARS) and a custom control cabin.

At the same time, LOTOS Petrobaltic is preparing their supply vessel, Bazalt II, as a dedicated operational platform for the Leopard, including adapting it to receive the LARS system and the custom configured control cabin, along with additional peripheral systems.

The 3000m-rated Seaeye Leopard is the top-selling electric work vehicle of its class and the most powerful of its size in the world, enabling it to tackle large and complex work tasks previously performed by much larger hydraulic systems.

At half the size of an equivalent hydraulic work vehicle, operators find the Leopard more agile and responsive and able to handle stronger currents and wave motion. It can also tolerate higher environmental temperature ranges and has a considerable acoustic advantage for survey work over hydraulic equivalents.

The 3000m Seaeye Leopard is the most powerful work robot for its size in the world with the versatility to tackle large and complex work tasks performed by much larger hydraulic systems.

The supply vessel Bazalt II is being configured as a dedicated operational platform for the Seaeye Leopard.

LOTOS Petrobaltic implements the strategic objectives of the ORLEN Capital Group in the exploration and production of hydrocarbons.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Grzegorz Zajfert

Miliana Shipmanagement Ltd

+48 500 002 419

Email Grzegorz Zajfert

www.lotos.pl

19 April 2023

SAAB SEAEYE LEOPARD FOR SPANISH NAVY SUBMARINE ESCAPE AND RESCUE

A £multi-million complete Saab Seaeye Leopard system has been supplied to the Spanish Navy for submarine escape and rescue, and underwater intervention.

Saab Seaeye Leopard: the most powerful electric work vehicle of its size in the world.

The NATO Support and Procurement Agency (NSPA) acquired the Seaeye Leopard electric remotely operated robotic vehicle system for the Spanish Navy to fulfil the responsibilities of the International Submarine Escape and Rescue Liaison Office and provide diving support.

It is the first codification by NATO for a remotely operated vehicle meeting their standards. The Leopard also met the Spanish Navy’s full ISO/IEE 15288 standards for remotely operated vehicles, along with their standards for the control cabin.

The Leopard can locate and survey a distressed submarine using its array of sonar systems and cameras to provide both colour zoom and low-light black and white video images for rescue planners. In urgent rescue situations the Leopard can work tirelessly 24 hours a day, for days on end in challenging conditions.

According to the information provided by the Spanish Navy through NSPA the Leopard will also contribute enormously to the Spanish Navy underwater intervention capability, especially in the areas of salvage operations, underwater search and reconnaissance and diving support activities.

Assisting in the procurement process has been Saab Seaeye’s Spanish-based distributor, Marine Vision, who will also engage in on-going support.

Life support

To help keep the crew alive, the Seaeye Leopard can transport and insert pods carrying emergency life support stores into the submarine — and attach ventilation hoses. For debris clearance the Leopard has powerful work-class manipulators, along with a six-inch rotary disc cutter and a 38mm anvil cutter.

The complete package includes a tether management system which acts as a subsea garage for the Leopard and from which it is flown when reaching the operational depth. The Leopard was chosen over its hydraulic alternative as the Leopard is typically 50% more efficient, 30% more compact and 50% lighter than an equivalent hydraulic vehicle.

Umbilical cables and handling systems are also significantly smaller and lighter, leading to lower deck loading requirements, smaller deck footprints, smaller vessel requirements and smaller transportation needs.

Air transportable

Included is a pilot’s control cabin and the entire system, or relevant free-swimming or tether-management configurations, is in the process of being certified for air transportation aboard an Airbus A400M to fulfil a global role in rescue operations.

Powerful and manoeuvrable

The most powerful of its size in the world, the Seaeye Leopard has 11 powerful thrusters and with its iCON™ intelligent control is more highly manoeuvrable in strong currents than a hydraulic vehicle and, being acoustically quieter, can produce more accurate sonar data.

Saab Seaeye’s intelligent control system offers pilots better handling characteristics — including pitch and roll stabilisation — for best quality survey data, whilst delivering stable flight even when fitted with large tools and transporting heavy loads.

Importantly, iCON™ gives clear and enhanced information to the operator and pilot whilst independently managing each device on the vehicle, including auto redundancy, ensuring the vehicle keeps working even with multiple equipment damage.

Simulator

Included in the procurement is a complete simulator system for pilot training that will simulate the operation of the Leopard during a rescue mission.

The Spanish Navy’s Saab Seaeye Leopard.

Complete Saab Seaeye Leopard system, including TMS and LARS installed on Spanish Navy vessel ‘Neptuno’.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

31 March 2023

FALCON FLIES DEEPER IN CANADA’S FIRST NATION WATERS

Ocean Dynamics has ordered a second, deeper-rated, Saab Seaeye Falcon for the inspection of instrumentation monitoring of the ocean around Canada’s northwest coast and First Nation coastal waters.

.jpg)

The 1000m-rated Falcon can be fitted with a wide range of tools, sensors and cameras and remain steady in strong currents and turbulent waters.

Already an owner of a 300m-rated Seaeye Falcon, Ocean Dynamics’ President, Josh Chernov says he chose the new 1000m-rated fibre optic Falcon because it can accommodate HD cameras and has the flexibility for integrating more advanced technologies.

Josh Chernov says the Falcon has proved to be reliable and able to stay working for longer than other underwater vehicles — and has better quality video.

Ocean Dynamics supports the University of Victoria’s Ocean Networks Canada programme of 50 instrumentation platforms and six observatories, plugged into over 900 kilometres of fibre-optic cable on the seafloor. The network provides marine scientists and coastal communities internet access to data for ocean management, disaster mitigation, and environmental protection.

Along with an inspection role, the Falcon will be assisting in the removal and replacement of instrumentation platforms and cabling when needed.

The world’s most successful system of its class, the Falcon’s winning concept comes from packing five powerful thrusters and an intelligent distributed control system into a small, easily manhandled metre-sized vehicle that can adopt different tools and sensors for undertaking numerous intricate and demanding tasks whilst mastering strong cross currents.

Ocean Dynamics supports inshore and offshore ocean science and exploration.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Josh Chernov

Ocean Dynamics

+1 250 867 4995

Email Josh Chernov

www.oceandynamics.ca

27 February 2023

SAAB UK CONTINUES FAREHAM GROWTH

Saab UK’s Fareham-based Seaeye business hosted local MP, Suella Braverman, 24th February 2023, as she visited their new site that is bringing jobs and investment to Fareham.

Saab UK’s new facilities in Fareham, UK.

Fareham-based Seaeye, a world leader in underwater robotics, has been expanding rapidly recruiting skilled jobs locally. The new site in Segensworth sees Saab’s presence grow to 8,400 m2 (83,000 ft2) as part of a multi-million-pound investment and more than 100 new jobs being created.

The Rt Hon Suella Braverman KC MP visited the site to meet with Saab UK’s senior management team, to hear about the further growth being planned in Fareham and to see the progress being made on the new facilities. Commencing shortly the move is expected to complete in the Autumn.

In November 2021 Saab UK’s Seaeye business, a world leader in underwater robotics, secured a contract from Ocean Infinity for their new electric work remotely operated vehicles (eWROV) which are being developed and built in Fareham. The new eWROV product, is the world’s most capable and intelligent all-electric, work-class underwater robot. This is the latest addition to the Seaeye underwater portfolio used across a variety of offshore energy sectors, ocean science and defence. Its electrification is the key to its improved performance and sustainability-related attributes.

The Rt Hon Suella Braverman KC MP, said:

“It was a pleasure to be back with Saab in Fareham and to see first-hand how this local success story continues to grow. There are so many exciting job opportunities being offered for a wide variety of skillsets, doing meaningful and interesting work both here at home and abroad.”

Dean Rosenfield, Managing Director of Saab UK, said:

“Saab has been in Fareham for many years now and we are keen to continue our commitment to the local community. The success of Seaeye has seen us grow here over the years and I expect this to continue with further expansion to come as we increase our UK production activities.”

Preview tour of new facilities by Suella Braverman MP.

Suella Braverman visiting Saab UK’s new Fareham facilities hosted by Saab UK Group MD Dean Rosenfield, Seaeye MD Jon Robertson and team.

eWROV has the in-built capability to be operated by onshore command and control centres. A reduced need for on-site personnel offers considerable savings to the user, as well as improving safety and reducing emissions by reducing the need for large support vessels and by removing the need to fly in personnel using helicopters.

Saab Seaeye is world leader in electric underwater robotics.

Saab UK is a national Ltd company that operates across the length and breadth of the United Kingdom. We bring together the best of Swedish innovation and British engineering. Directly and indirectly through our supply chain we support thousands of British jobs and provide technologies that keep people and society safe.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Nicolas Clark-Majerus

Saab UK

+44 (0)7856 001 858

Email Nicolas Clark-Majerus

www.saab.com/UK

23 February 2023

UCO WINS HUGE CONTRACT WITH SAAB SEAEYE FALCON FLEET

Underwater Contracting (UCO), owners of the world’s largest fleet of Saab’s Seaeye Falcons, has expanded to 27 vehicles as they win one of the largest contracts in the global aquaculture sector.

Seaeye Falcon is capable of handling UCO’s hugely successful FOOVER mortality recovery system.

The agreement will see the Falcon fleet working 365 days a year over multi-year contract terms and providing a range of services in Europe, North America and Australia.

Specialists in aquaculture, UCO, has successfully deployed Seaeye Falcon underwater vehicles since 2018, for animal welfare and installation integrity across aquaculture sites across three continents.

In that time, they have productively utilised the power and intelligence of the Falcon system when designing and developing industry-leading technologies, including their FOOVER Mortality Recovery system, NETFIX Net Repair system and G-LANCE Cage Cleaning system.

They chose the Seaeye Falcon as the world’s top selling underwater robotic vehicle in its class and for its versatility, being able to be utilised not only in aquaculture, but in the offshore energy and maritime sectors as well.

With a reliability record totalling over one million hours underwater, the Seaeye Falcon is a compact metre-sized vehicle that can be fitted with role-changing, heavy tooling systems. With five powerful thrusters and intelligent control architecture, the Falcon is capable of precise manoeuvrability amongst complex structures and strong currents. The Seaeye Falcon is designed and manufactured at Saab UK’s Fareham site.

Underwater Contracting Ltd (UCO), based in Aberdeen, is a leading provider of underwater services for the maintenance of aquaculture sites throughout Scotland, North America, Canada and Europe and is part of the Ocean Marine Group.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Mick Bower

Underwater Contracting Ltd

+44 (0)1224 872861

Email Mick Bower

www.underwatercontracting.com

30 January 2023

HABITAT-SAVING ALGORITHM HELPED BY SEAEYE FALCON

Scientists at the Washington Department of Fish and Wildlife (WDFW) have acquired a second Saab Seaeye Falcon underwater robot. The Seaeye Falcon is used to conduct surveys of marine fish and invertebrates in Washington’s Puget Sound, where some rockfish populations were fished to levels that threatened extinction.

High-definition stereo camera and paired lasers are used to assess individual fish size and the density of fish in a measured field of view.

The surveys are used primarily to monitor the recovery of rockfish listed under the United States Endangered Species Act, but also provide information on the unique geological features in Puget Sound. The WDFW has also used their Falcon to survey the habitat surrounding U.S. Navy bases in Puget Sound to meet Federal permitting requirements, locate and recover lost equipment and conduct special studies of sea urchins and sea cucumbers.

The new Seaeye Falcon is a 300m rated system and equipped with a high-definition fibre-optic video system capable of collecting higher resolution imagery than WDFW’s original Falcon, which has seen over 4000 hours of use since 2007.

“The HD imagery collected with the new vehicle will greatly improve our ability to detect small and cryptic rockfishes, leading to more precise estimates of abundance, and will be used to train machine-learning algorithms being developed to partially automate the video review process, which is expected to substantially improve survey and post-processing efficiency,” explains research scientist Robert Pacunski.

Not pushed around

“The Falcon can precisely manoeuvre amongst the cracks and crevasses of complex underwater rock formations favoured by rockfish and has the power not to be pushed around by the current,” says Robert Pacunski.

Specialised equipment fitted to the Falcon includes a pair of parallel lasers and a stereo camera for assessing individual fish size and the density of fish in a measured field of view. An Imagenex multi-frequencing gyro-stabilised sonar is used to identify target habitats and avoid uncharted obstacles (for example, derelict fishing gear, subsurface electrical and telecommunications cables). Depending on survey needs, the vehicle can be fitted with a conductivity-temperature-depth meter to collect data in real-time for examining linkages between physiochemical water quality parameters and fish distribution/abundance.

The world’s most successful system in its class, the Falcon’s winning concept comes from packing five powerful thrusters and an intelligent distributed control system into an easily manhandled metre-sized vehicle that can adopt different tools, cameras and sensors for undertaking numerous intricate and demanding tasks in strong currents.

Assisting the acquisition of both Saab Seaeye Falcons was the local distributor in North America, Jack Roberts of Symphotic TII Corporation.

New Research Vessel Salish Rover from which WDFW’s new deep-rated Seaeye Falcon will be deployed.

The lasers are spaced at 10cm and are used primarily to calculate the width of our survey transects, but also to give us some indication of fish size.

Scientist Bob Pacunski with the WDFW’s original Falcon rigged with the research team’s heavily front-loaded survey system that has spent 4000 hours underwater.

The Washington Department of Fish and Wildlife is dedicated to preserving, protecting, and perpetuating the state’s fish, wildlife, and ecosystems while providing sustainable fish and wildlife recreational and commercial opportunities.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Robert Pacunski

WDFW Marine Fish Science Unit

+1 425 379 2314

Email Robert Pacunski

www.wdfw.wa.gov

12 January 2023

SEAEYE FALCON THRIVES IN CROCODILE-INFESTED WATERS

ASI Group have deployed a Saab Seaeye Falcon robot into crocodile-infested waters in East Africa. The crocodiles have been preventing manual inspection of remote inland underwater structures supporting East Africa’s power generation.

Imaging the smallest anomalies in the murkiest waters.

The curious crocodiles soon lost interest in the Seaeye Falcon as the robot ventured into rivers and reservoirs, as well as inside structures and tunnels, to inspect and survey the wide variety of infrastructure supporting five power stations.

Inspecting assets, critical to the continuous operation of facilities that provide electricity to over 20 million people, was within the scope of work by ASI, a global specialist in inland waters.

It required several inspection operations to assess the many underwater structures including intake screens, stoplogs guides, long tunnels, drop shafts, and stilling basins.

A truck crane was used to remove covers and stoplogs, and to launch the Falcon into a variety of access locations. The crane’s long boom kept personnel a safe distance from the crocodiles.

Even in extremely murky waters the smallest anomalies in structures were captured on the Falcon’s sonar by ASI operators.

Deep in the jungle

Areas previously considered inaccessible were surveyed, proving the versatility of the multi-beam sonar system provided by ASI.

In one location, the Falcon was lowered over 20 metres by crane to reach a basin surrounded by jungle.

At another location, the entire boat and survey gear were hand-carried 300 metres down rocky terrain to access a stilling basin requiring assessment.

The remote access technology that enables inspection and survey operations in locations that are inaccessible and unsafe for personnel was also used to access water-filled tunnels.

Using the Falcon for tunnel inspection avoids dewatering, which risks the tunnel’s infrastructure, including collapse.

Millions depend on data collected

With millions of residents depending on the energy produced by the power stations, a clear understanding of the infrastructures’ status is essential to enable proactive scheduling and greater reliability of the assets.

The survey data collected was used by ASI to construct 3D models of the various water control structures. By reviewing and comparing the collected data with known build-data, a clear understanding of the installations’ conditions was established.

Repeatable assessment across the locations utilising remote systems and acoustic inspection devices allows detection of anomalies and their change over time.

Considerable savings

ASI reports that considerable cost savings have been achieved by deploying the advanced systems protocol using their Falcon configured with an integrated sonar survey package and inertial navigation system

Although small enough to be easily manhandled, the Falcon, with its iCON™ intelligent control architecture, combined with five powerful thrusters, allows precise manoeuvrability in strong currents and amongst complex structures, whilst loaded with sensors, tooling and systems typically found on much larger robotic vehicles.

The Seaeye Falcon is the world’s most popular robot in its class with a reliability record covering over a million hours underwater.

Inspecting water-filled tunnels saves de-watering.

ASI Group Ltd. (ASI) has been an industry leader in underwater inspection, maintenance and repair and biofouling monitoring and control services since 1987.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Merry Dang

ASI Group Ltd.

+1 905 643 3283

Email Merry Dang

www.asi-group.com

14 December 2022

KITE FLYING WITH FALCON

Flying kites underwater to generate electricity is an innovative renewable energy concept being installed in the Faroe Islands, supported by SJH Diving and their new Saab Seaeye Falcon.

Animation — courtesy Minesto — tidal kite movement and array.

(To see Video copy this link: https://minesto.frontify.com/d/C2QTuQ6m2RRx/media-library/show/eyJpZCI6Njg1MDI0NSwidGltZXN0YW1wIjoiMTY3MTAxMTc0MCJ9:frontify:0qGuDDFnUnWXtDan6YGAaLyOxDYXO1OjPayqlF37nmI)

The subsea kite turbine is a unique concept created by developer Minesto to generate electricity in tidal streams and ocean currents using the principle of flying a stunt kite in the wind.

By swooping through the water in a constant figure of eight motion on a tethered cable, the kite turbine accelerates through the water considerably faster than the actual flow speed.

The electricity generated from a kite turbine is several hundred times greater than from a stationary turbine.

In support of multiple kite installations, Faroes-based SJH Commercial Diving will deploy their Seaeye Falcon underwater robot for inspecting power-cable runs along the seabed to the shore and inspecting and cleaning foundation points.

Best in strong currents

Símin Jákup Højsted of SJH Diving says the Falcon was the best choice for strong currents compared to five competitive makes of vehicles.

SJH Diving has been involved with the project for over two years.

Minesto is a marine energy technology developer founded in 2007, since when it has successfully developed its unique marine energy technology called Deep Green.

The ability to also operate at low velocities makes Minesto’s Deep Green the only technology to be cost-efficient in both tidal and ocean currents.

Mastering currents has helped the Falcon become the world’s top selling robot in its class, along with its being an easy to use, small, intelligent, powerful, and multi-tasking with a reliability record covering over a million hours underwater.

SJH’s Seaeye Falcon comes with a multi-beam sonar, single function and five function manipulators, a cathodic potential probe and a fully-kitted cleaning skid.

SJH Commercial Diving vessel dedicated to the support of the array of subsea kite installations.

Faroe Islands.

Minesto subsea kites awaiting installation.

Swooping in a constant figure of eight motion accelerates the kite through the water considerably faster than the actual flow speed and generates electricity several hundred times greater than from a stationary turbine.

Minesto subsea kite turbine.

A Seaeye Falcon can be rated either 300m or 1000m and fitted with a wide range of cameras, sensors and tooling.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Símin Jákup Højsted

S.J.H. Commercial Divers

+29 852 8464

Email Símin Jákup Højsted

http://www.sjh.fo/english/home

28 November 2022

NUCLEAR SURVIVOR

A proven survivor — the Saab Seaeye Tiger has spent five years working in nuclear storage ponds at Sellafield, one of the most highly radioactive and highly alkaline places on the planet for a robotic vehicle.

The Saab Seaeye Tiger has spent five years working in nuclear storage ponds — one of the harshest places on the planet for a robotic vehicle.

Celebrating this record-breaking achievement are the Sellafield team and Saab Seaeye engineers who nuclear-proofed the Tiger to survive an extremely corrosive environment whilst sorting 15kg spent fuel rods in the nuclear ponds.

Les Barker of Sellafield’s innovation team says:

“The Tiger-N has improved the amount of work we can do in the ponds in a day — sometimes doing 10 times what we’ve managed in the past.

The Tiger’s reliability also means that the people using and maintaining them are getting less exposure to radiation.”

To limit radiation dose risk to operators and maintainers, in an environment that is highly hazardous to humans, the Tiger was adapted to ensure systems and materials would survive extreme corrosion to limit exposure time spent on maintenance and cleaning.

Exposure to radiation is carefully limited as unplanned downtime would quickly exhaust operators’ safe working period in any one year.

The adapted design is called Tiger-N, for nuclear, with six having been delivered to the site so far.

Not only does the Tiger-N need to be corrosion-proof, but also systems such as its quick-change tool skids. These include an under-slung manipulator skid, a four-function forward facing manipulator skid, sludge scoop dredger skid, cutting skid and an under-slung water-jet cleaning skid.

“We’ve now used these robots to move 20 per cent of the pond’s inventory into safe modern storage. It has gone from, ‘let’s try something’, to a major success which has reduced the hazard the pond presents,” concludes Sellafield’s Les Barker.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Ruth Hutchison

Sellafield Ltd

+44 (0)1946 786227

Email Ruth Hutchison

16 November 2022

FALCON HELPS PROTECT MALDIVES CORAL REEFS

A Saab Seaeye Falcon underwater robot has helped complete the first-ever systematic scientific survey of the waters of the Maldives — the lowest-lying nation on earth.

Saab Seaeye Falcon fitted with special stereoscopic camera array. Nekton Maldives Mission © Nekton 2022.

The Maldives is just 1.5 metres above sea level on islands of coral reef atolls. Globally, coral reefs account for 32% of known biodiversity. They are seen as the ‘rainforests of the ocean’, yet at least 97% could be lost with a 1.5-degree temperature rise.

The Nekton Foundation in partnership with the Maldives Marine Research Institute undertook the mission to understand the Maldives’ ecosystem to help create extensive new protected marine areas and strengthen the resilience of coral reefs to protect the islands from increasingly intense storms and erosion caused by climate destabilisation.

As an official partner to the mission, Saab Seaeye donated use of the Falcon to work alongside human-occupied submersibles, autonomous systems and research technologies.

The Falcon and other submersibles and divers collectively documented the extensive biodiversity of the ecosystem from shallow waters to 1000 metres.

Analysis of video transects from the Falcon has revealed 107 fish species and 130 organisms that live on the seabed, such as coral, sponges and algae. Analysis is ongoing with more species expected to be identified.

The Falcon also recorded charismatic megafauna such as turtles and sharks. These specific observations will be used to support projects engaged in long-term population assessments.

The research recorded extensive coral bleaching at many locations. In other locations, however, exceptionally healthy coral reefs were found. This offers hope that healthy coral reefs can thrive, particularly in areas where cold water upwellings prevent bleaching. These areas may be critical to support coral propagation projects.

Marine life in high definition

To enable scientists to document the biodiversity of the ocean around the Maldives, Nekton scientists devised, tested, improved and deployed a novel methodology for using the Falcon for video transects in shallow waters on the complex topography of coral reefs and operating in areas of strong currents.

Two sets of cameras were positioned on the vehicle, one set forward facing and the other set downward facing. They were spaced 80cm apart and at inward angle of 8 degrees ready to be calibrated for stereoscopic video recording.

The same system was used by snorkelers and other submersibles to complete video transects in an identical manner and at different depths.

Challenge of shallow waters

“Surging currents in the shallows and sheer subsea cliffs made this one of the most challenging operations on the mission,” says Mission Director, Oliver Steeds.

“Only the Falcon could handle the swell surges and powerful currents, including up-currents and down-currents,” he explains.

Renowned for its ability to hold steady in strong currents while filming and manoeuvring, the Falcon is the world’s top robot in its class with a reliability record covering over a million hours underwater.

Nekton is a not-for-profit UK-based research foundation working with the University of Oxford and a wide range of partners engaged in the scientific exploration and protection of the ocean.

The Seaeye Falcon was able to transect steep reef cliff faces and maintain stability in strong currents and swell surges. Nekton Maldives Mission © Nekton 2022.

Nekton is a not-for-profit research foundation working with the University of Oxford and a wide range of partners to accelerate the scientific exploration and protection of the ocean.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Oliver Steeds, OBE

Nekton Foundation

+44 1865 309685

Email Oliver Steeds

www.nektonmission.org

9 November 2022

SAAB SEAEYE IN ANGOLAN ‘RIG TO REEF’ PROJECT

The transformation of an oil platform into an artificial reef is underway in Angola.

The transformation of an oil platform into an artificial reef is underway in Angola.

The transformation of an oil platform into an artificial reef is underway in Angola.

It is the first platform in Africa to be decommissioned in a project led by environmental quality services company, EQS, with a Saab Seaeye Falcon underwater robot deployed for the task.

Chief Technical Officer at EQS, Carlos Rodrigues says, “By operating the Seaeye Falcon and all its related capabilities, EQS is supporting its aim to fulfil specific works in a safe and cost-effective manner delivering accurate and relevant information.”

The Falcon is assisting in the survey and mapping of all underwater components, including checking the wellhead, pipelines and the surrounding maritime environment.

Baseline environmental conditions are determined by taking water and sediment samples at several stations and at different depths, focussing on biological matter, namely zooplankton, phytoplankton, and benthos.

Significant marine growth already exists throughout the structure with abundant marine life already in the area for populating the rig when toppled on its side to become an artificial reef.

Once decommissioning is complete, a series of surveys will be scheduled to monitor the evolution of marine growth on the newly created reef.

EQS selected the Seaeye Falcon for its ability to handle an array of cameras, sensors, tooling and complex data gathering systems that include a digital multi-frequency profiling sonar.

Having reached the end of its service life the rig’s transformation into a reef is being undertaken under the auspices of The Ministry of Mineral Resources, Oil and Gas of Angola.

EQS helps offshore energy clients navigate the complex environmental regulatory landscape including compliance, HSE subjects, and business liabilities.

The mission involves a multi-disciplinary team from different companies and sectors of activity, including marine biology, hydrographic surveys, quality inspectors and personnel specialised in survey equipment such as the Falcon.

Future work involves clearing an area of fish nets, restoring platform signalling and marking, positioning of signal buoys and confirmation of pipeline locations along with the surveys to monitor marine growth.

The platform is already presenting significant marine growth.

The platform is already presenting significant marine growth.

EQS team viewing video images from the Saab Seaeye Falcon of the marine growth and marine animal activity at the platform.

EQS team viewing video images from the Saab Seaeye Falcon of the marine growth and marine animal activity at the platform.

Multiparametric probe.

Multiparametric probe.

Seaeye Falcon underwater robot being deployed for inspection of the abandoned platform that will become an artificial reef.

Seaeye Falcon underwater robot being deployed for inspection of the abandoned platform that will become an artificial reef.

.jpg) EQS selected the Seaeye Falcon for its ability to handle an array of cameras, sensors, tooling and complex data gathering systems that include a digital multi-frequency profiling sonar.

EQS selected the Seaeye Falcon for its ability to handle an array of cameras, sensors, tooling and complex data gathering systems that include a digital multi-frequency profiling sonar.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Carlos Rodrigues

EQS

+351 934 422 810

Email Carlos Rodrigues

www.eqs-fze.com

6 October 2022

AUSTRALIA’S SUPER-SIZED SALMON FARMER GETS A FIFTH FALCON

Huon Aquaculture, Australia’s second largest salmon farmer, has purchased another Saab Seaeye Falcon underwater robotic vehicle to support its marine and environmental operations.

Falcons inspect and maintain Huon’s critical subsea farm infrastructures.

This brings Huon’s Falcon fleet to five. Huon sees the Seaeye Falcon as a vital farming tool for surveying and monitoring their marine leases in South East Tasmania, Australia.

Huon purchased their first Falcon in 2015 and have, since then, been operating Falcons 24 hours a day, seven days a week.

Dr Shea Cameron, Huon’s Subsea and Remote Systems Manager, says the Saab Seaeye model is invaluable to the company’s farming operations:

“Our dive and mooring teams use Falcons to inspect and maintain our critical subsea farm infrastructure.”

He says their Falcons spend more time in the water than any of the others in Huon’s large fleet of remotely operated vehicles that range from large specialist net cleaning vehicles to smaller eyeball class systems.

Dr Cameron adds that the Saab Seaeye Falcons have consistently proven to be a tough and capable platform, easy to service and with excellent manufacturer support.

“They can be rebuilt and repaired quickly and sent back out to work — making Huon a proud Saab Seaeye Operator!” Dr Cameron says.

As the world’s top selling robot in its class, the Saab Seaeye Falcon’s global success comes from being an easy to use, metre-sized, intelligent, multi-tasking, powerful, five-thruster strong, highly maneuverable robot with a reliability record covering over a million hours underwater.

Huon has been operating Falcons 24 hours a day, seven days a week since 2015.

The world’s top selling robot the Falcon’s global success comes from being an easy to use, intelligent, powerful, highly manoeuvrable robot with a reliability record covering over a million hours underwater.

Saab Seaeye is world leader in electric underwater robotics.

Huon Aquaculture, founded in 1986, produces over 25,000 tonnes of salmon annually and is fully committed to farming and environmental stewardship in a responsible way.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Dr Shea Cameron

Huon Aquaculture Group Limited

+03 6295 8115

Email Dr Shea Cameron

www.huonaqua.com.au

29 September 2022

FALCON IS WINNING STRATEGY FOR HYPROPS NIGERIA

Hyprops Nigeria Limited has chosen the Saab Seaeye Falcon as the best robotic vehicle resource for increasing their long-term footprint in Nigeria.

“Our current customers demand the Falcon as a trusted, easy-to-use resource,” says Hyprops.

“The Falcon has proven over the years to be capable and versatile, with a lightweight and portable construction that gives us the ability to perform diverse and difficult-to-access subsea operations.”

Incorporated in 1997, Hyprops provides a wide range of services to the Nigerian offshore oil and gas sector and adding the Falcon as their resource is in keeping with the Federal Government’s initiative to increase indigenous participation in the sector.

Hyprops describes the benefits expected from their Falcon:

- Depth options ranging from 300m to 1000m

- iCON™ intelligent control system allowing the option of customisation of the vehicle and giving the pilot total control

- Easy access to spares and a choice of tools and accessories

- Open frame construction allowing ease of fitting various sensors and tooling to meet client requirements

- Five-function manipulator arm, wire cutter and brushes enabling light work intervention

Hyprops conclude that the Falcon will give them the ability to meet the constant and vital need to inspect pipelines, flowlines, risers, vessels and platforms in both shallow and deep-water projects.

Already the world’s top selling robot of its class, the Saab Seaeye Falcon’s success comes from being an easy-to-use, metre-sized, intelligent, powerful, five-thruster-strong, highly manoeuvrable, multi-tasking, robot with a reliability record covering over a million hours underwater.

Hyprops will deploy the Falcon on subsea inspection, survey, light-intervention and maintenance services for current and future projects in the Nigerian market where their clients include international and indigenous oil companies.

Hyprops: “Customers demand the Falcon as a trusted, easy-to-use resource.”

Hyprops Nigeria Limited provides a wide range of services to the Nigerian offshore oil and gas sector

Saab Seaeye is world leader in electric underwater robotics.

Hyprops Nigeria is a fully owned Nigerian company which has provided oilfield support services to the oil and gas industry in Nigeria since 1997 and is looking to expand into other markets.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Mrs Chinweoke Okpalaji

Hyprops Nigeria Limited

+234 1 2717297

Email Mrs Chinweoke Okpalaji

www.hyprops.com

7 September 2022

SAAB SEAEYE PARTNERS MALDIVES MISSION

A Saab Seaeye Falcon underwater robotic vehicle will join a fleet of submersibles on the Nekton Maldives Mission to help the Maldives Government carry out the first systematic survey and sampling of the Maldives from the surface to 1000 metre depths.

The Nekton Maldives Mission will establish a ‘baseline health check’ on the status of Maldives ocean. (Photo credit: Saab Seaeye)

As an official partner, Saab Seaeye has donated the use of a Seaeye Falcon to work alongside human-occupied submersibles, autonomous systems and research technologies.

The Maldives state is 99% ocean and 1% land, sitting on average 1.5 metres above sea level. As a result, the nation faces a growing threat from rising seas.

For the first time, the mission will establish a ‘baseline health check’ on the status of the Maldives ocean and provide data to scientists and policy makers worldwide to enable the protection of critical nurseries, spawning habitats and related ecosystems.

The Nekton Maldives Mission, 4th September to 7th October, will help create extensive new protected marine areas and ensure the ocean continues to provide for the Maldivian people.

Nekton is a not-for-profit UK-based research foundation working with the University of Oxford and a wide range of partners to accelerate the scientific exploration and protection of the ocean.

The Falcon is the world’s top robot in its class with a reliability record covering over a million hours underwater.

Nekton Foundation is a not-for-profit research foundation and a registered charity that works with a wide range of partners to accelerate the scientific exploration and protection of the ocean.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Lisa Hynes

Nekton Foundation

+44 7966 272256

Email Lisa Hynes

www.nektonmission.org

25 August 2022

JAPAN GOES 3D WITH FALCON

Japan’s 3D survey company, Windy Network, has chosen a Saab Seaeye Falcon underwater robotic vehicle for its global operations.

Japanese submarine ‘Kairyu’ surveyed using 3D high-precision acoustic sonar.

They intend deploying the Falcon on a wide range of missions, including academic research, marine archaeology, fishery surveys and construction installation studies, such as offshore wind energy sites.

For such a variety of operational undertakings the versatile Falcon is an ideal choice, says Windy Network.

The Falcon can be fully loaded with cameras, sonars and tooling, yet will remain highly manoeuvrable and stay steady even in strong currents and turbulent waters.

Already the world’s top selling robot in its class, the Saab Seaeye Falcon’s success comes from being an easy to use, metre-sized, intelligent, powerful, five-thruster, multi-tasking vehicle with a reliability record covering over a million hours underwater.

It will join Windy Network’s fleet of remotely operated vehicles — a vital resource for an innovator in the research and development of 3D measurement systems and operator of Japan’s residential Ocean Research Training Facility.

As a marine survey 3D measurement company and developer, Windy Network aims to process huge amounts of acquired data with high accuracy and efficiency, corrected for ship vibration for a seamless display.

Supporting Windy Network in their acquisition was Saab Seaeye’s distributor in Japan, Marimex.

.jpg)

The Saab Seaeye Falcon’s reliability record covers over a million hours underwater working at a vast array of tasks using a variety of cameras, sonars and tooling.

Windy Network is a marine survey 3D measurement company and developer.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

18 August 2022

FALCON AS EXPEDITION YACHT RESCUE ROBOT

For expedition yacht Dapple a Saab Seaeye deep-rated Falcon robot has been chosen as a standby rescue resource for emergency recovery of their manned submersible.

Expedition yacht Dapple in Bora Bora.

In addition, the 1000 metre-rated Falcon comes fully equipped for undertaking a wide range of scientific research and survey operations.

Dapple’s dive manager, Marc Taylor, says that the Falcon is a proven commercial choice, so fits their criteria, “and it makes sense because we already have a Falcon aboard another vessel in our fleet.”

Operators worldwide favour the Falcon, a small, intelligent robot with the power and task range typically found in much larger systems.

Not only can owners view underwater from aboard the yacht in high-definition images transmitted by the roaming Falcon, but the robot has many other uses.

It can examine the hull millimetre-by-millimetre, recover items from the seabed, cut ropes and cables, and clean critical fittings.

Specialist cameras, survey systems and manipulator arms can be fitted for research and survey missions.

For Dapple, the Falcon is equipped with an extensive range of technology including HDTV cameras, a multifrequency scanning sonar, multibeam sonar, laser system and an eventing suite. It also comes with both a three jaw and a five-function manipulator, each with rope cutters, along with hydraulic cable cutter and rotary cleaning brush.

Although the Falcon’s key role is recovery of Dapple’s submersible, for general diving safety the Falcon can survey a dive site beforehand, then watch over a diver when below and transport items back and forth during a dive.

The Falcon’s global success comes from being a small metre-sized, yet powerful, highly maneuverable, multi-tasking, easy to use vehicle, depth rated up to 1000 metres and enhanced with Saab Seaeye’s revolutionary iCON™ intelligent control system.

It has a trusted reliability record covering over a million hours of undersea operations, working in the most challenging environments, mastering turbulent waters and strong currents whilst remaining stable during filming, scanning and undertaking delicate tasks.

.jpg)

The world’s top selling robot with a million hours’ reliability record underwater, the Saab Seaeye Falcon can be fitted with a host of cameras, sonar and tooling for a wide variety of tasks.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Marc Taylor

M/Y DAPPLE

+689 877 986 56

Email M/Y DAPPLE

17 June 2022

SAAB SEAEYE AT GOODWOOD’S FESTIVAL OF SPEED

Future Lab, the innovation pavilion at Goodwood’s Festival of Speed, 23 – 26 June 2022, is featuring Saab Seaeye’s pioneering underwater robotic technology.

Goodwood says Future Lab presents “cutting edge new technologies that will change the way we live tomorrow”.

Visitors to the innovation pavilion can see visions of future and emerging technology set to inspire industry enthusiasts and the next generation of scientists, inventors and explorers.

Saab Seaeye is showcasing three revolutionary robotic systems highlighting the company’s inventive vision that has advanced and led underwater robotics for over 30 years.

On show will be Sabertooth, the world’s first deep-rated roaming and hovering robot that can operate in both autonomous and tethered modes, enabling fully flexible dual operations from a single platform whilst filming, surveying and operating tooling.

It was Sabertooth that successfully found the wreck of the Endurance, sunk 3000m below the Antarctic ice during Shackleton’s ill-fated expedition in 1915.

The new Seaeye eWROV, also on show, is a breakthrough in powerful electric work robotics. It is a considerably more environmentally friendly green alternative to the equivalent traditional hydraulic heavy work robotic systems.

Also featured is the Seaeye Falcon. Its innovative design has made it the world’s most popular underwater robot capable of undertaking a huge range of tasks. It is widely used by marine scientist for research and by innovators as a development platform.

The world leader in electric underwater robotics, Saab Seaeye has the largest range of electric robotic vehicles in the industry, operating across industrial, defence and scientific sectors.

Innovative new electric work robot, eWROV, complete with pioneering new all-electric seven-function work-class Seaeye manipulators.

Sabertooth deployed into Antarctic waters in the successful search for the Endurance.

.jpg)

Sabertooth — the world’s first deep-rated roaming and hovering robot that can operate in both autonomous and tethered modes.

Falcon — the world’s most popular robot of its class and widely used by innovators as a development platform, shown here with a Blueprint Lab manipulator arm.

Photo courtesy Dominic James and Goodwood.

Photo courtesy Dominic James and Goodwood.

Photo courtesy Dominic James and Goodwood.

Saab Seaeye is world leader in electric underwater robotics.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

10 June 2022

FALCON BEST FOR JAPAN’S RENEWABLES SAYS SHIBUYA

For Japan’s growing offshore renewable sector, Shibuya Diving Industry Ltd (SDI), chose another Saab Seaeye Falcon for their Falcon fleet.

Shibuya chose the Seaeye Falcon as the best robot for supporting Japan’s floating wind turbine operations.

“As a diving company, an underwater robotic vehicle is a vital resource for extending our operational capability,” says Shibuya “and found the Falcon was the top choice globally amongst diving companies.”

“To find the best vehicle, we assessed the range on the market and found that the Seaeye Falcon is the most widely used robot in the offshore power generation business with the longest proven reliability record.”

Shibuya mainly deploy the Falcon for floating turbine work as, in a crowded and mountainous country, the search for sites in Japan is going offshore with floating turbines the favoured option in the deep waters off the rugged coast.

Experienced in renewables

Shibuya have 10 years’ experience in offshore wind power generation, being early to trial robots for the emerging use of floating turbines for power generation.

Shibuya recognises that robots are best placed to advance the use of floating turbines by confirming the stability of deep mooring anchorages and for carrying out periodic inspections of the floating structures.

Success in the floating offshore wind power generation business has extended Shibuya’s operations into tidal power generation and ocean current power generation.

For Shibuya, the Falcon’s multi-tasking capability with easy role change makes it an ideal choice. It is also easy to use, highly manoeuvrable and able to master turbulent waters and strong currents and remain stable whilst undertaking robust or precision tasks.

The reliability record of the Falcon, covering over a million hours of undersea operations, working in challenging environments at many different tasks, was particularly reassuring to Shibuya.

Diver safety

The Falcon plays a vital safety role by undertaking missions too hazardous for divers and where the depth of water and strength of current are dangerous for divers to operate, such as surveying fishing grounds and fishing reefs prior to turbine installation — and periodic inspection of mooring anchors and chains.

The addition of the Falcon to diving operations improves diver safety and increase efficiency, Shibuya says, by pinpointing and examining locations of interest before sending down divers.

Also, during the diving operation the Falcon robot can keep a watchful eye — and save dive time by transporting tools and parts back and forth.

Planting seaweed forests

Important in Japan’s development of offshore technologies for power generation is maintaining harmony with the natural environment and enabling marine ecosystems and floating turbines to co-exist and promote sustainable fishing.

To this extent, Shibuya is involved in the proliferation of seaweed forests in power generation areas by releasing seaweed seedlings to promote an increase in fishery resources.

They have conducted seaweed bed surveys and regeneration in more than 50 locations throughout Japan.

Shibuya’s Seaeye Falcons continue to play an important role in supporting this important sustainable enterprise as the renewable energy business continues to grow in Japan.

Supporting Shibuya in their acquisition of their additional Falcon was Saab Seaeye’s distributor in Japan, Marimex.

Shibuya chose the Seaeye Falcon as the best robot for supporting Japan’s floating wind turbine operations.

The Falcon’s ability to hold steady in turbulent waters and strong currents, makes it ideal for inspection of floating turbine chains and anchorages, says Japan’s Shibuya Diving company.

Saab Seaeye is world leader in electric underwater robotics.

Shibuya Diving Industry (SDI) is a leader in Japan’s offshore renewable energy sector.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Akihiro Sugiuchi

Shibuya Diving Industry

+81 (0)463 50 3350

Email Akihiro Sugiuchi

shibuya-diving.co.jp

29 April 2022

PORTUGUESE NAVY HYDROGRAPHY TRAINING WITH EQS FALCON

Training exercises aboard a Portuguese Navy hydrographic vessel have been completed by EQS (Environment Quality Services) using their Saab Seaeye Falcon robot.

Saab Seaeye Falcon robot deployed during training exercises aboard a Portuguese Navy hydrographic vessel with EQS (Environment Quality Services).

Teams from the Portuguese Hydrographic Institute and EQS undertook several exercises over three days on board the Portuguese Navy vessel Andrómeda, commanded by First Lieutenant Ribeiro de Carvalho, off the coast of Portugal.

The main objective was to verify the operability and functionalities of the systems in their various configurations along with the spectrum of commitment, says Carlos Rodrigues of EQS.

This included basic navigation, object collection, integration of sonar systems and exercises with a USBL positioning system.

The Seaeye Falcon remotely controlled underwater vehicle allows for extended observation of the sea floor and underwater structures, explains Carlos Rodrigues, making it possible to increase the ship’s scientific research capabilities.

Chosen for its power and task range, typically found in much larger robotic vehicles, the Falcon’s module-focussed iCON™ intelligent distributed control architecture makes adding and changing systems easy and future-flexible for evolving technologies.

The world’s top selling robot of its class, with a reliability record covering over a million hours underwater, the Falcon’s proven success comes from being a reliable, easy to use, metre-sized, intelligent, powerful, five-thruster, highly manoeuvrable, multi-tasking, robot, depth rated to 1000 metres.

Teams from the Portuguese Hydrographic Institute and EQS undertook several exercises involving the Falcon, including basic navigation, object collection, integration of sonar systems and exercises with a USBL positioning system.

The crew aboard the Portuguese Navy vessel Andrómeda, off the coast of Portugal, commanded by First Lieutenant Ribeiro de Carvalho.

The world’s top-selling robotic vehicle in its class, performing thousands of hours of undersea operations, the Falcon offers the versatility, power and control intelligence needed to perform a vast array of tasks.

Saab Seaeye is world leader in electric underwater robotics.

EQS provides cost-effective solutions to complex and routine environmental projects.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

Carlos Rodrigues

EQS

+351 934 422 810

Email Carlos Rodrigues

www.eqs-fze.com

25 April 2022

INTELLIGENT MUSCLE AT OTC

A new extremely powerful and intelligent electric manipulator can be seen on Saab Seaeye’s Stand 1406 at the Ocean Technology Conference, Houston, 2 – 5 May 2022.

.png)

Intelligent muscle with Seaeye’s new work-class manipulator, eM1-7, as precise as it is strong.

The pioneering breakthrough is Saab Seaeye’s new eM1-7 seven-function all-electric work-class manipulator.

As powerful as a hydraulic equivalent, it is more reliable and more dexterous.

Seaeye eM1-7’s micrometre precision comes from each of its seven joints having extremely accurate force and position feedback coupled with their own smart distributed microprocessor for intelligent, intuitive and precision arm control.

Visitors to the exhibition stand can also hear more about other innovations that are changing the face of underwater enterprises.

Saab Seaeye’s innovative new environmentally friendly electric work vehicle, called eWROV, matches the power of a 250 hp hydraulic work class system, but is easier to operate, more precise, acoustically quieter, more reliable, needs less maintenance and has a much lower lifetime cost.

Already the world leader in electric underwater robotics, Saab Seaeye’s eWROV joins the largest range of electric robotic vehicles in the industry.

This includes the multi-role 3000m rated Sabertooth, the world leading roaming and hovering robot that can operate in both fully autonomous and tethered modes, enabling fully flexible dual operations from a single platform fitted with cameras, sonars and tooling.

Two Sabertooth robots have succeeded in finding the wreck of the Endurance, sunk 3000m below the Antarctic ice during Shackleton’s ill-fated expedition in 1915.

Innovative new electric work robot, eWROV, complete with pioneering new all-electric seven-function work-class Seaeye manipulators.

Sabertooth deployed into Antarctic waters in the successful search for the Endurance.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

10 March 2022

BREAKTHROUGH ROBOTICS AT OCEANOLOGY INTERNATIONAL

Highlighted at Oceanology International in March is Saab Seaeye’s new eco-responsible all-electric work-class robot, eWROV.

The all-electric eco-responsible Seaeye eWROV fitted with two all-electric Seaeye eManips — both on show at Oceanology International.

With the performance of a 250hp hydraulic work vehicle, eWROV is easier to operate, more precise, acoustically quieter, more reliable and needs less maintenance than hydraulic equivalents.

Empowering progress towards a sustainable future eWROV can be operated from onshore control centres, is resident-ready and will play an important role in future autonomous vessel fleets.

Also on show is eManip, Saab Seaeye’s all-electric seven-function work-class manipulator. As powerful as its hydraulic equivalent, eManip is more accurate, more reliable and more dexterous.

Each of eManip’s seven joints has its own inbuilt intelligence for intuitive millimetre precision control in addition to force and position feedback.

At the core of their robotics vision is Seaeye’s module-focussed iCON™ intelligent distributed control architecture that is future-flexible, enabling easy adoption of evolving technologies.

Visit us on Stand H100 and find out how Saab Seaeye is advancing robotics for a sustainable world.

For more information contact:

Matt Bates

Saab Seaeye Ltd

+44 (0)1489 898000

Email Matt Bates

www.saabseaeye.com

3 March 2022

Japan’s growing offshore wind industry is gaining a Saab Seaeye Cougar XTi underwater robotic vehicle for cable burial inspection and other roles.

.jpg)

The Saab Seaeye Cougar XTi for Kayo Engineering can operate precisely in strong currents whilst fitted with cameras, sonars and tools.

Kaiyo Engineering has acquired the 2000m rated Cougar, incorporating intelligent control architecture, for deployment from a 250ton mother ship, the Kaiyo Maru.

The ship is one of a fleet of vessels belonging to Kaiyo Engineering, the only privately owned research and observation company in Japan.

The Cougar XTi adds to Kaiyo’s portfolio of Saab Seaeye robots that include a Leopard and a Falcon.

In addition to its cable inspection role, the Cougar will also be used by Kaiyo Engineering to cover additional Leopard work.

Worldwide, Saab Seaeye robots play a dominant role in offshore renewables, as they are technologically suited for the challenges involved in building and maintaining structures and interconnections.

The Cougar XTi is a particular favourite. With its six powerful thrusters it can hold steady in cross currents and operate with precise manoeuvrability whilst fitted with a wide array of equipment.

Kaiyo’s Cougar comes with four Imenco cameras, a Tritech SeaKing sonar, Nortek DVL and station-keeping software, and a five-function heavy duty manipulator with camera.

Its intelligent iCON™ behaviour-based ecosystem endows each device with its own microprocessor for individual control and real-time feedback, in a modular future-flexible system that allows for further development and innovation.

The entire Kaiyo Cougar XTi operational configuration includes a launch and recovery system (LARS), tether management system (TMS) and 20ft control cabin and workshop.